Wafer Automated Optical Inspection

Cost Effective 2D Automated Optical Inspection (AOI) on Wafer Platform

-

Micro and Macro defect detection

-

Effectively screened wafer lithography, etching, ion deposition, metal wiring and CMP process defect like coating, bridging, peeling, residues, corrosion, scratches, polishing defects etc.

-

Inner crack and bonded wafer water mark infra-red inspection

-

Copper width, seal ring, TSV via and other measurement metrology

-

Bright field and dark field inspection ▪ Robust technology, with high speed multi core processor computing

-

Featuring intelligent defect re-validation

-

Self learning Neural network deep learning defect ADC

Cost Effective

-

Fast and effective methodologies

-

Reliable Consistency – Enabling wafer sampling/metrology and full wafer inspection

-

Auto Defect Classification – Minimize human dependent error and disposition inconsistency

-

Automated Wafer Handling – Minimize human induced handling error

OPTO Photonic

Custom Optomechanical solution which allows users to position a focused laser spot with extreme precision.

When probing, a laser point is isolated over a wide-spanning surface area enabling precise, pixel-level measurements across a broad wavelength range.

The 10X optical zoom allows precision sample observation and spot location.

Example specifications for a custom designed probe test cell.

WID 120 Reader

State-of-the-art ID reader will easily handle your most challenging scribes. The longer it works, the faster it gets.

-

Revolutionary integrated RGB illumination

-

Fully automatic exposure control

-

Code shift compensation

-

High and fast reading rates

-

Intelligent configurations handling

-

Precise fine tuning

-

Additional external RGB light source

-

OCR, Barcode, DataMatrix and QR code

-

Easy graphical user interface

-

Easy integration

Best Cost of Ownership:

Achieve highest yield

Increase of MTBA/MTBF

Decrease of MTTR

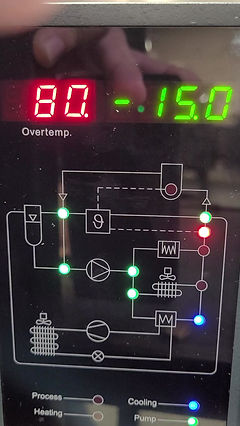

Thermal Chucks

Advanced Temperature Test Systems offers a wide variety of Thermal Chucks designed for use on probers like APEX, their solutions can also be used on Accretech, TEL and Electroglas. Technological leadership assures the most advanced products available for thermal applications.

-

Hot and Cold applications

-

Liquid and Air chillers

-

-65C to +200C range

-

Intelligent Dry-Air Control

-

Low Thermal Resistance

-

Best temperature accuracy and uniformity

-

Triax connection standard

-

Multi-sense multiple temperature sensors

-

Same Chuck for Liquid or Air Chiller